Click on the image to open in a New Tab.

Video Transcript

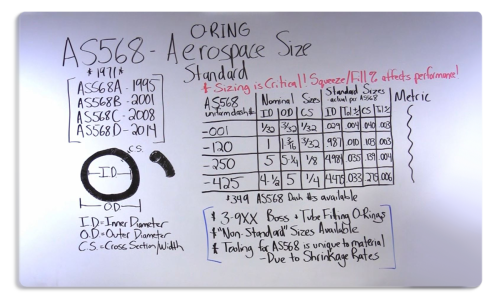

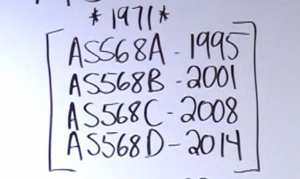

Today we’re going to talk o rings. We get frequent calls, request for quotes, emails, regarding o ring and o ring sizing. Today we are going to run through and explain how o rings are sized and talk a little bit about the language of o ring sizing. o rings are sized using AS568; which is an aerospace standard that was published back in the seventies. The original AS568 was published in 1971, since then there have been several versions A through D – you can see the years that they were published – 1995, 2001, 2008, and 2014 is the latest.

The Three o ring Sizing Dimensions

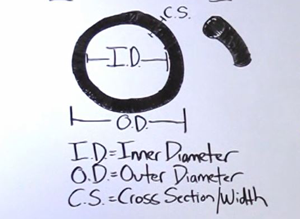

When we talk o rings, we are of course are talking about circular seals, but more importantly, when we say o ring, we mean the o-shaped cross-section – or round cross-section. Because a number of seals are round but the cross-sections are not circular. So today we are talking about the circular cross-section seals.

O rings are sized using three different dimensions. There’s the ID which is the inner diameter. There is the OD which is the outer or outside diameter, and then there’s the cross-section which is also known as the width. So those are the three dimensions that are most important.

AS568 Universal Table

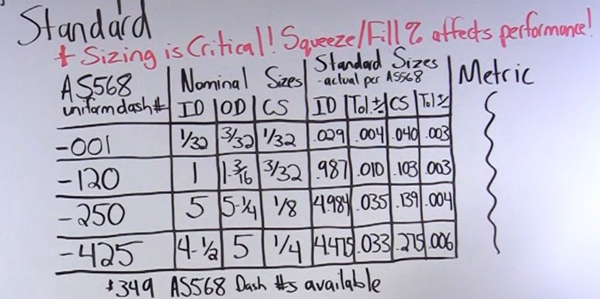

As we look at the standards themselves. The first thing that I do want to clarify is that sizing is important when it comes to o rings. You can get close to dimensions, but you want to be careful because those o rings are sized using a squeeze and fill percentage, which is critical in sealing and it does affect the overall sealing of the application. So if you have questions about the groove or groove size console an application engineer.

The AS568 dash numbers refer to a specific ID and cross-section. The OD is listed when you look at tables, or in particular when you look at the tables for a manufacturer, but it’s not necessarily needed.

The AS568 numbers are uniform across manufacturers. It does not matter who. You are going to see the same dimensions and you’re also going to see the same tolerances.

So in our example, we’re looking at a -001 o ring. That o ring has a 1/32 inch ID and it has a 1/32 inch cross-section. We can look at it from a nominal standpoint and we can also look at it from an actual standpoint. That actual standpoint- it would be an ID of .029 inches with a tolerance of + or – .004. The cross section would be .040 with a tolerance of .003 inches. Again, this is universal across manufacturers. As long as it’s AS568 referenced, all of these dimensions should be the same.

As you look at the dash numbers – as they go up higher you get into thicker cross-sections. So for instance, a -120 o ring is 1 in by 3/32 of an inch – actually translates to .987 + or – .010 with a cross section of .103 + or – .003.

Again, use the table, use any manufacturer – we have Parker in particular – use the table provided by the manufacturer and then use tools. We don’t necessarily recommend a caliper, although you can get close to those dimensions. Also, you can use an o ring cone which would get you the actual AS568 reference for that part.

All in total, there are 349 AS568 dash numbers that are available – these are tooled-up. Any o ring manufacturer should have 349 sizes available.

Non-Standard O Ring Sizes

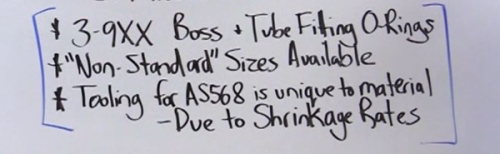

Now in addition to your standard AS568 dash numbers, when it comes to o rings, I do also want to reference that there are 3-9XX sizes available – few limited. These are considered boss or the tube-fitting o rings – sized specifically for threads and the end tube fittings.

There are also nonstandard sizes that are available, and those sizes depend on the manufacturer. They’ll be a list of available sizes that have been tooled up outside of the AS568 references.

One last note as you’re talking about AS568 sizes, do keep in mind that tooling for these sizes at manufacturers is unique to the material or the compound that the o ring is made up of and this is due to shrinkage rates and shrinkage rates on material varying. So the tooling itself will have to vary with that.

I appreciate the time. If you have any questions, feel free to contact our website at espint.com or industrial seal.com.