Whitepapers On Whiteboard

Summary

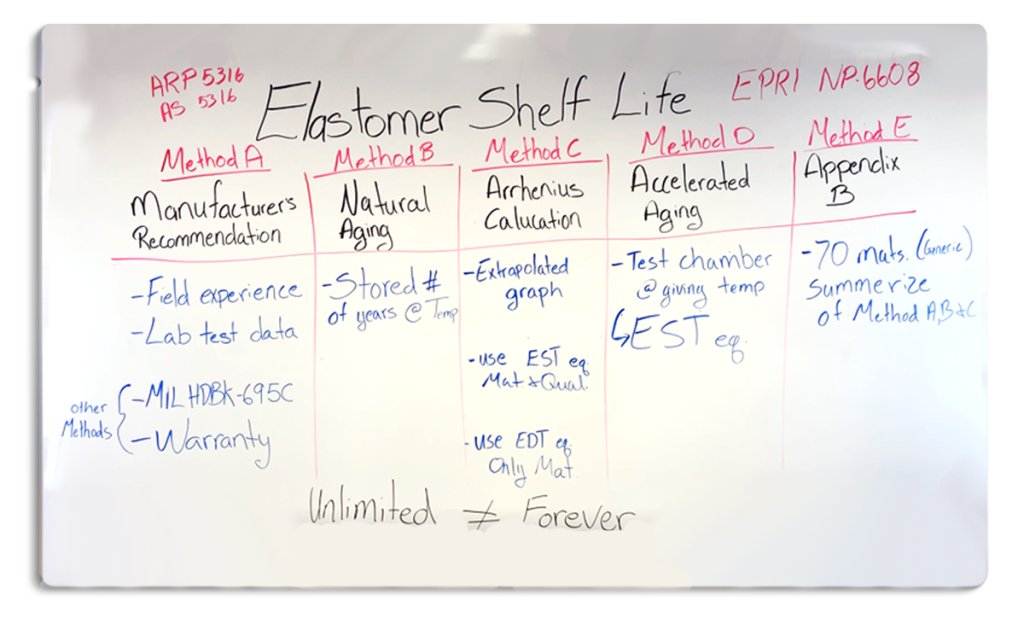

“Shelf life” is the maximum time (beginning with manufacture date) that an o-ring or elastomeric seal – with proper packaging and storage, becomes unable to meet its original specifications.

Aerospace Recommended Practice (AP 5316) is the most comprehensive basis for establishing shelf life, however, it is not a binding specification.

Let’s look at a few Methods at which shelf life is being calculated.

Click on the image to open in a New Tab.

Video Transcript

5 Methods to Obtain Elastomer Shelf Life

Some materials are listed as unlimited, however unlimited is not equal to forever. For some companies, they use 25 to 30 years as unlimited shelf life. According to the study EPRI NP-6608, which is one of the references in ARP 5316, which replaced by Aerospace Standard 5316, in the study it talks about five different methods to obtain elastomer shelf-life.

1. Method A: Manufacturers Recommendation

It is acceptable to use field experiences data or lab test data, however, using military standardization handbook or rubber products or warranty, then other methods are recommended.

2. Method B: Natural Aging

Data is collected by products being stored for a number of years in an average room temperature. This method is time-consuming and yet it is a case-by-case basis.

3. Method C: Arrhenius Calculation

Shelf life can be obtained by using this extrapolated graph or EST equation, which requires materials in qualification data or using EDT equation and only materials data is needed.

4. Method D: Accelerated Aging

By using a test chamber at a given temperature, data can be obtained by measuring critical properties periodically until data drop below acceptable values. Then the EST equation can be used to estimate the shelf life.

5. Method E: Appendix B

Appendix B is where roughly 70 generic materials were summarized by using Method A, B, and c and is listed in years.